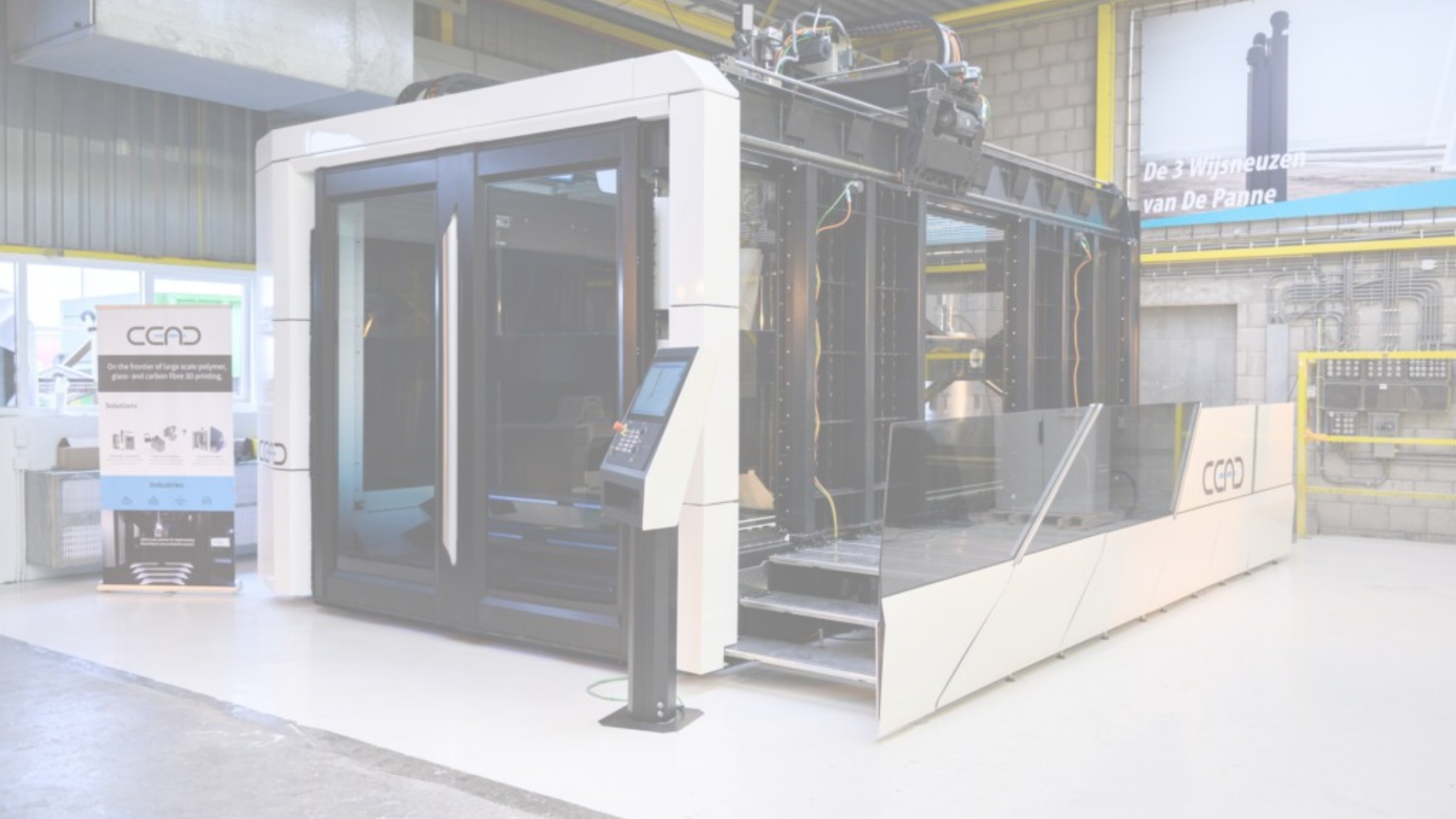

We build large format 3D printers

CEAD delivers technology and helps with the implementation of large format thermoplastic composite 3D printing solutions

We build large scale 3D printers

CEAD delivers technology and helps with the implementation of large scale thermoplastic composite 3D printing solutions

Our large scale additive manufacturing solutions

Discover your possibilities

The overall package provided by CEAD gives us full flexibility as a research institution. Besides size, flexibility and reliability were the main reasons for choosing CEAD’s AM Flexbot system.

The CEAD printer extends our capabilities towards larger parts, higher fiber contents and a wider range of polymers. The CEAD system was delivered very quickly — from order to installation was only 6 months.

“We were really happy with the service and product CEAD offered to us. They were willing to help us with concretizing our idea right from the start and steered us into the right direction. Also the final product was delivered just as we expected and saved us precious hours during the production of our car!”

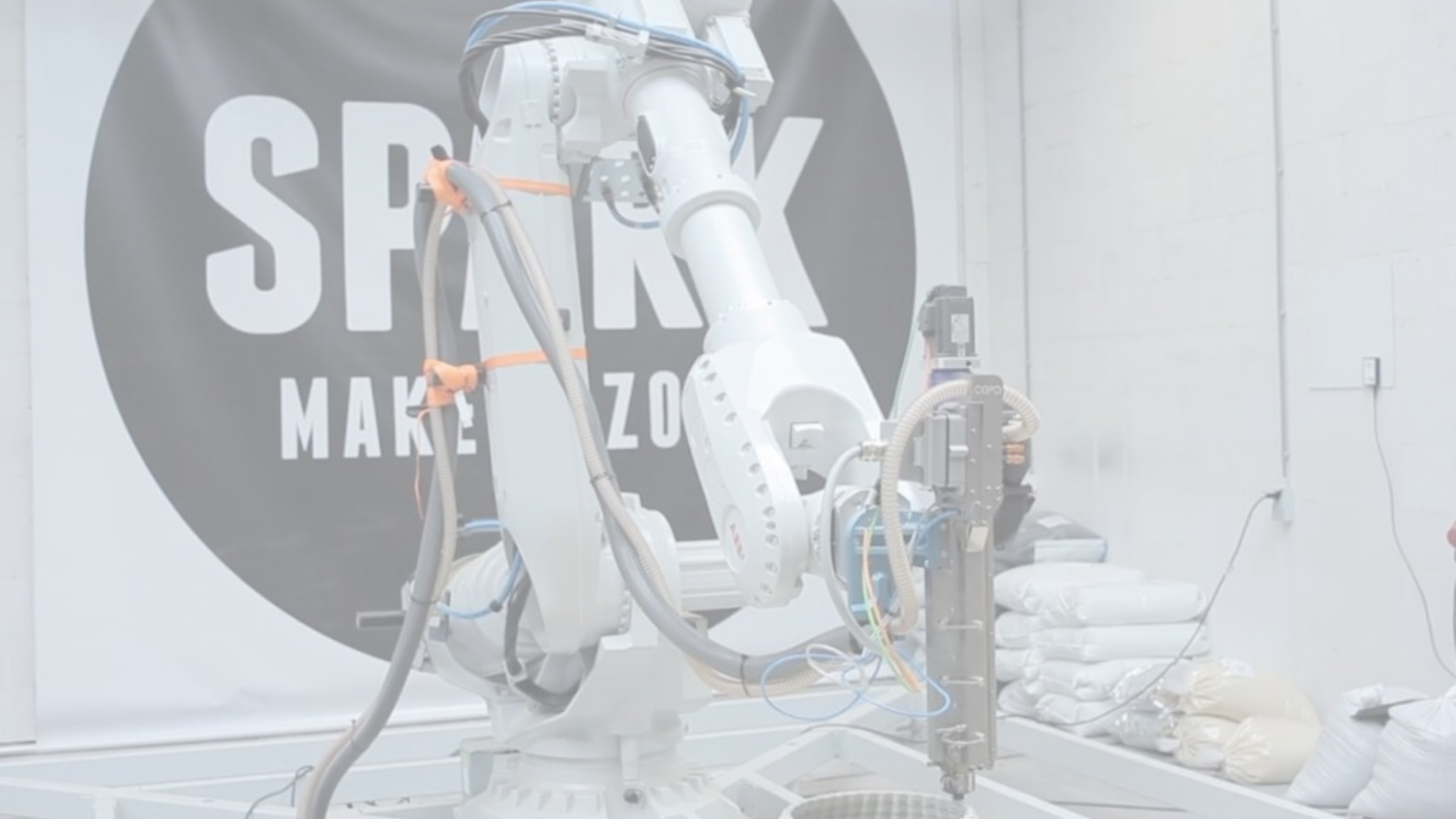

We are enthusiastic about the CEAD Robot Extruder and make new applications / shapes with it, such as a lampshade, rain barrels, flower pots, and doors of a classic Jeep. Because SPARK Makers Zone is an open lab, (potential) customers of CEAD can come here to print and experiment.

We have found the CEAD Robot Extruder to be the perfect tool for our needs. High throughput, high temperature, a wide variety of materials, 24/7 production possibilities, and relatively low weight, make it an ideal extruder for us.

With this 3D printer we can work faster, at lower costs and we have less manual labour.

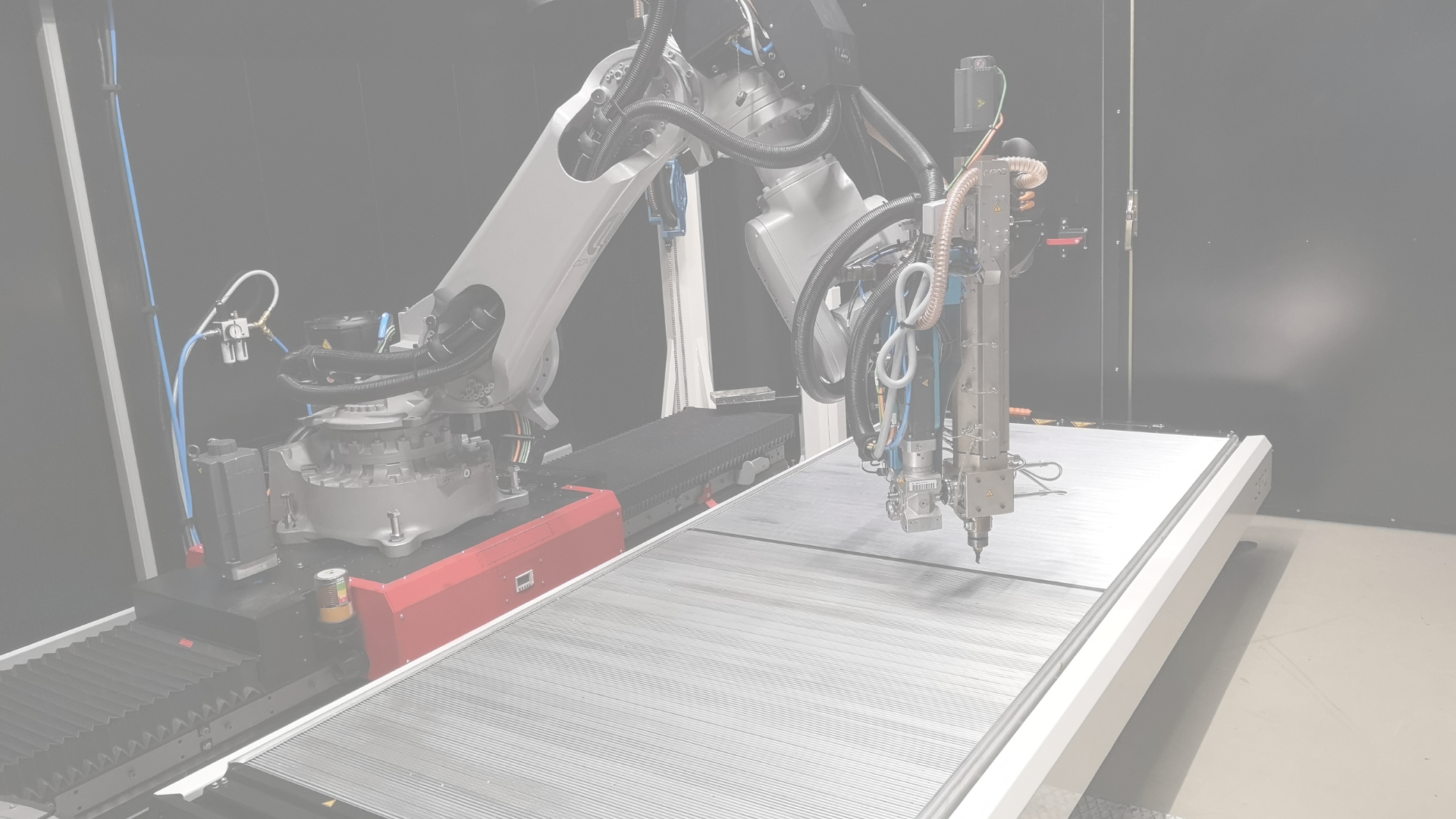

We are delighted to show an industrial solution from CEAD for multi-axis composite printing combining Comau’s robotics, CEAD’s Additive Manufacturing and our best in class CNC technology.

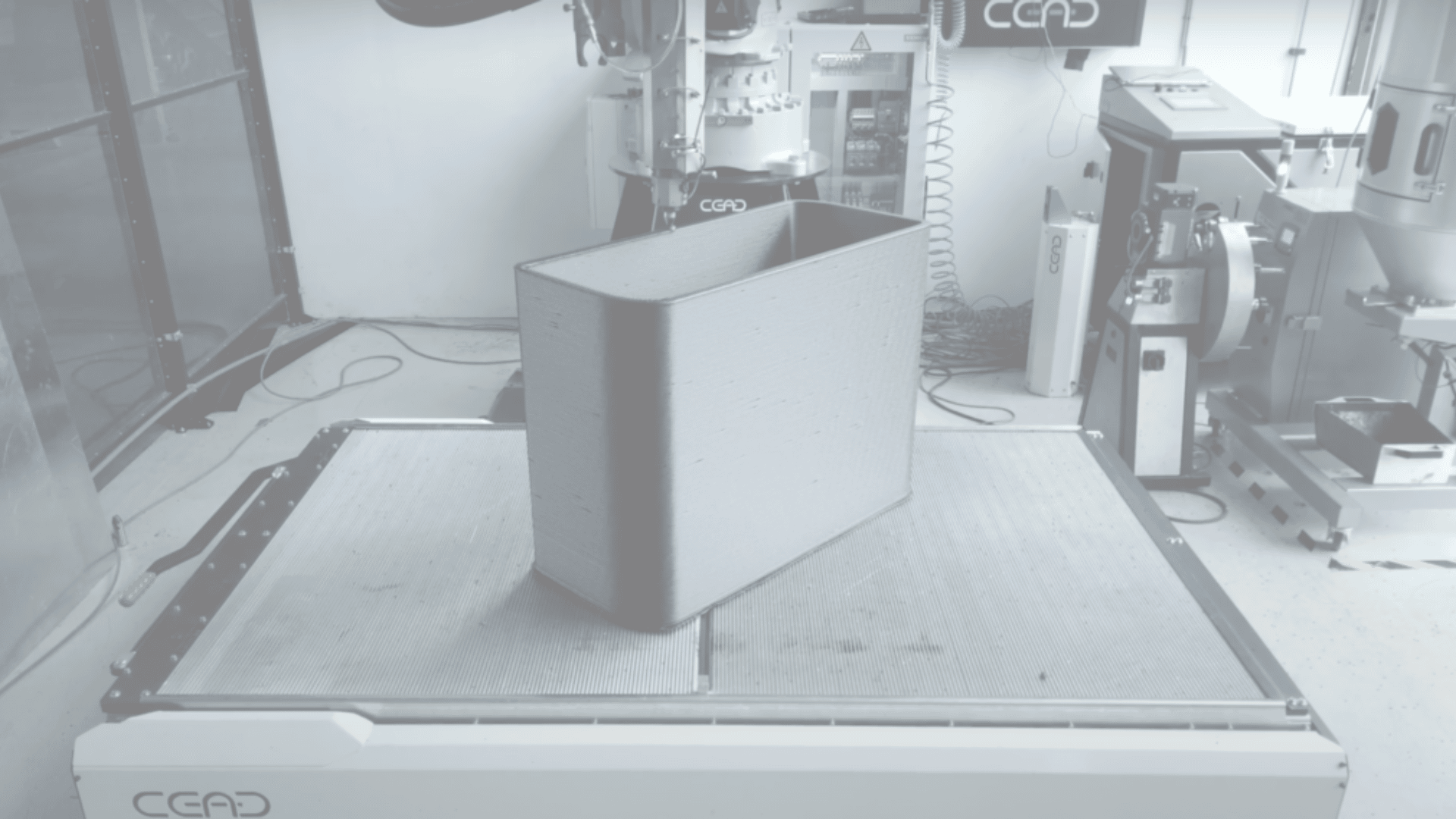

We are now 3D printing molds using 30% short glass fiber-reinforced polypropylene and cutting our labor time by 50%.

Due to CEADs constructive approach and innovative ideas we always collaboratively come up with the best solutions.

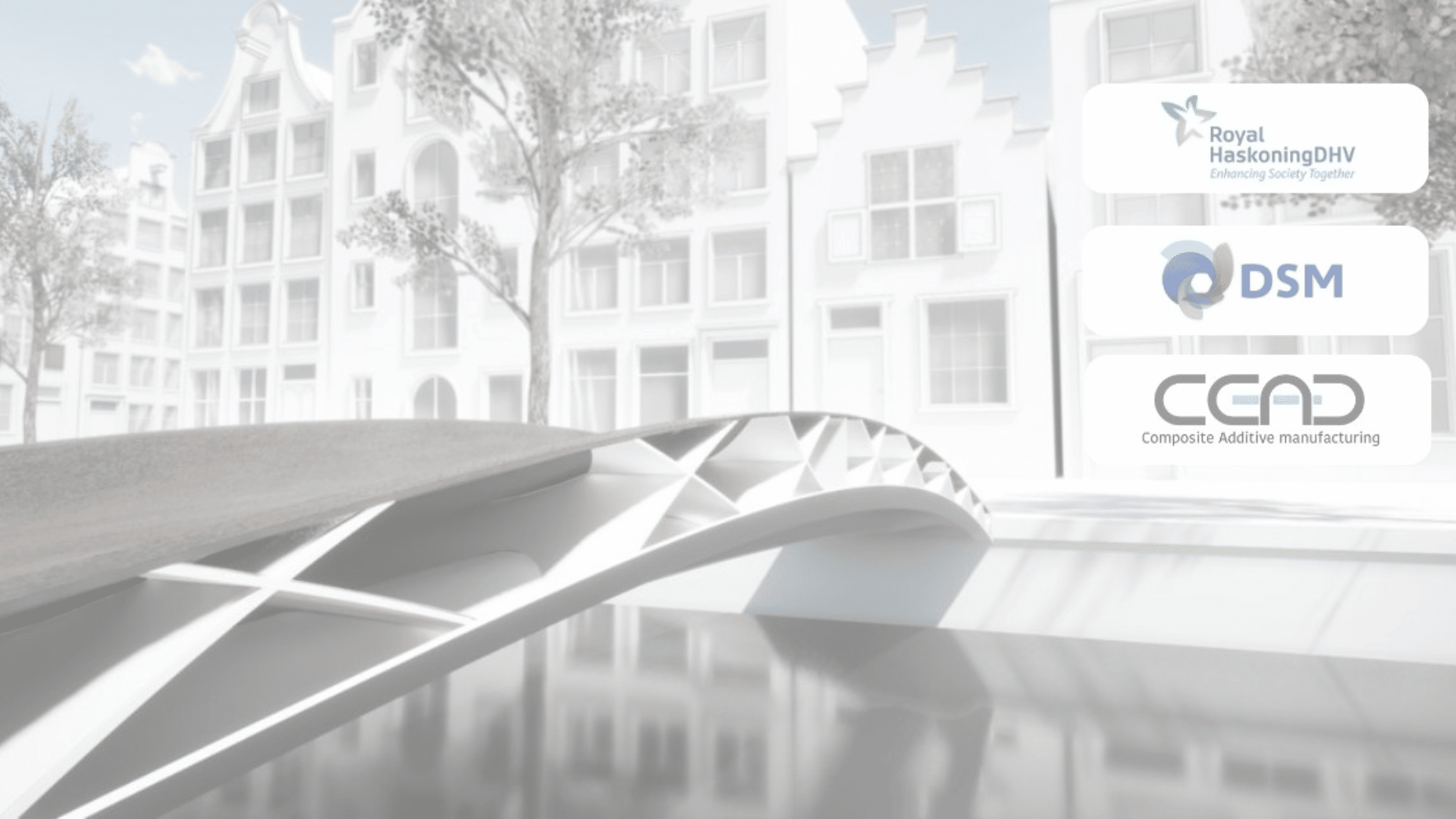

Fiber-reinforced polymer bridges are already well known for having a longer lifetime expectancy with lower life cycle costs compared to steel bridges. What’s new here is the use of a new 3D printing technology, enabling us to print large-scale fiber reinforced thermoplastic parts.

Discover your possibilities

The overall package provided by CEAD gives us full flexibility as a research institution. Besides size, flexibility and reliability were the main reasons for choosing CEAD’s AM Flexbot system.

The CEAD printer extends our capabilities towards larger parts, higher fiber contents and a wider range of polymers. The CEAD system was delivered very quickly — from order to installation was only 6 months.

“We were really happy with the service and product CEAD offered to us. They were willing to help us with concretizing our idea right from the start and steered us into the right direction. Also the final product was delivered just as we expected and saved us precious hours during the production of our car!”

We are enthusiastic about the CEAD Robot Extruder and make new applications / shapes with it, such as a lampshade, rain barrels, flower pots, and doors of a classic Jeep. Because SPARK Makers Zone is an open lab, (potential) customers of CEAD can come here to print and experiment.

We have found the CEAD Robot Extruder to be the perfect tool for our needs. High throughput, high temperature, a wide variety of materials, 24/7 production possibilities, and relatively low weight, make it an ideal extruder for us.

With this 3D printer we can work faster, at lower costs and we have less manual labour.

We are delighted to show an industrial solution from CEAD for multi-axis composite printing combining Comau’s robotics, CEAD’s Additive Manufacturing and our best in class CNC technology.

We are now 3D printing molds using 30% short glass fiber-reinforced polypropylene and cutting our labor time by 50%.

Due to CEADs constructive approach and innovative ideas we always collaboratively come up with the best solutions.

Fiber-reinforced polymer bridges are already well known for having a longer lifetime expectancy with lower life cycle costs compared to steel bridges. What’s new here is the use of a new 3D printing technology, enabling us to print large-scale fiber reinforced thermoplastic parts.

Revolutionizing windshield tool production with the Flexbot

Revolutionizing windshield tool production with the Flexbot REDU, the Lapland Education Center, provides state of the art training to young adults to create a competitive workforce. As such, REDU creates an important link between education and industry, granting companies access to the latest technologies whilst also training and providing their future workforce.

Long term partnership

CEAD supplies a total package when it comes to 3D printing solutions. We not only supply the technology and the machine, but also offer assistance with installation, offer assistance with product design, training, maintenance and support. We will help you build your production process from start to finish.

Meet CEAD at events

The possibility to attend conferences and events in person is here again, and we are excited to meet you at one of the following events. CEAD is attending events additive manufacturing and more.

View our agenda to meet CEAD and our large scale additive manufacturing solutions in person.